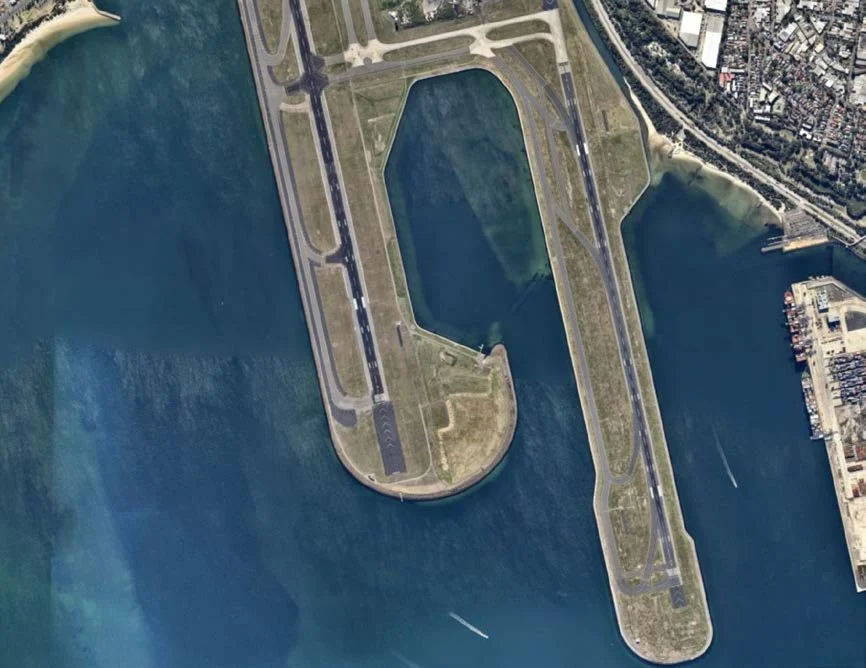

TL‑2000 (PRS) Spray Trial — Sydney Airport

A fast‑curing, non‑emulsion rejuvenation treatment applied on the western shoulder of Runway 16L/34R, demonstrating predictable return‑to‑service, friction safety, and lifecycle sustainability advantages.

Trial Dates

8 May 2020 & 18 June 2020

Application Rate

~1 kg/m² @ ~1 mm nominal thickness

Dry‑to‑Traffic

~30–45 minutes (weather‑dependent)

Application Modes

Airless sprayer & hand squeegee

Project Overview

Airfield Shoulder – Runway 16L/34R

Product:

PRS/TL‑2000 — viscous liquid composed of powdered dolomite, styrene, high‑quality bitumen and proprietary additives.

Application:

Spray wand/handpiece via airless sprayer in grooved areas; hand squeegee in non‑grooved areas.

Equipment:

Graco King 70:1 airless sprayer, COMP‑AIR C50 180 CFM compressor, hand squeegee.

Notes: tips sized to avoid blockage and ensure uniform coverage. Predetermined areas were marked to verify rate control.

Trial Areas & Conditions

Day 1 (8 May):

24°C air / 28.5°C pavement; wind 20.4 km/h NW; touch‑dry ~35–45 min depending on method.

Day 2 (18 June):

17.8°C air / 21.3°C pavement; wind 11.1 km/h ESE; touch‑dry ~30–38 min.

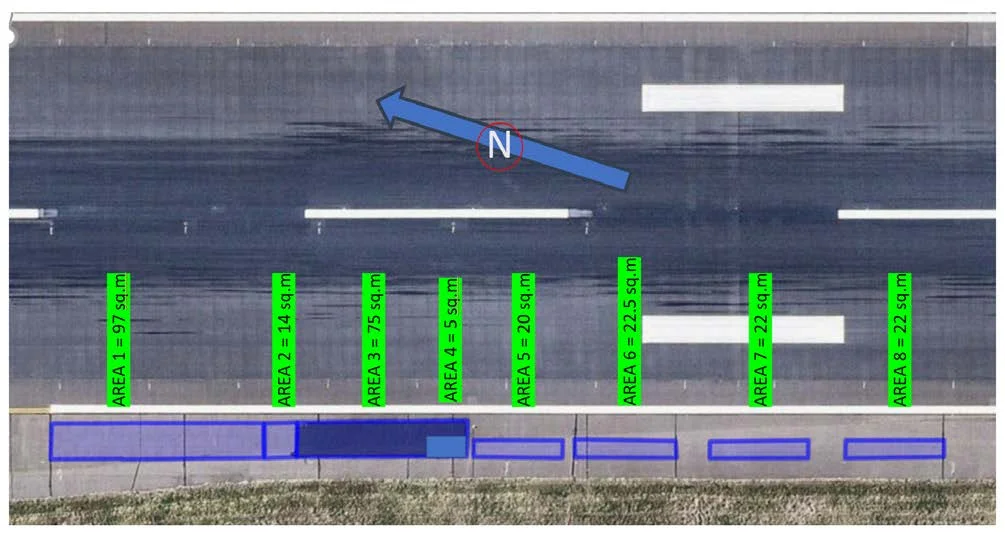

Patches:

Areas 1–8 (e.g., Area 1 ~97 m²; Areas 5–8 by squeegee). Xylene used in some spray mixes (2–10%) with blended product added to maintain ~1 kg/m².

Why This Method Is More Sustainable

Lifecycle Advantage:

Rejuvenation shifts programs from cyclical replacement to asset preservation, aligning with “perpetual pavement” principles and reducing capital and environmental cost over the network life.

We can prepare an NPV/payback comparison versus mill‑and‑fill for your specific climate, operations and access windows.

Application Summary

Rate control

Areas pre‑marked; typical target rate ~1 kg/m² at ~1 mm thickness.

Spray method

Airless sprayer with wand/handpiece; larger tips used to avoid blockage and ensure even fan.

Squeegee method

Used in non‑grooved areas to compare coverage and productivity.

Solvent usage

Limited xylene addition (≈2–10%) to aid spray; additional blended product applied to keep total mass ≈1 kg/m².

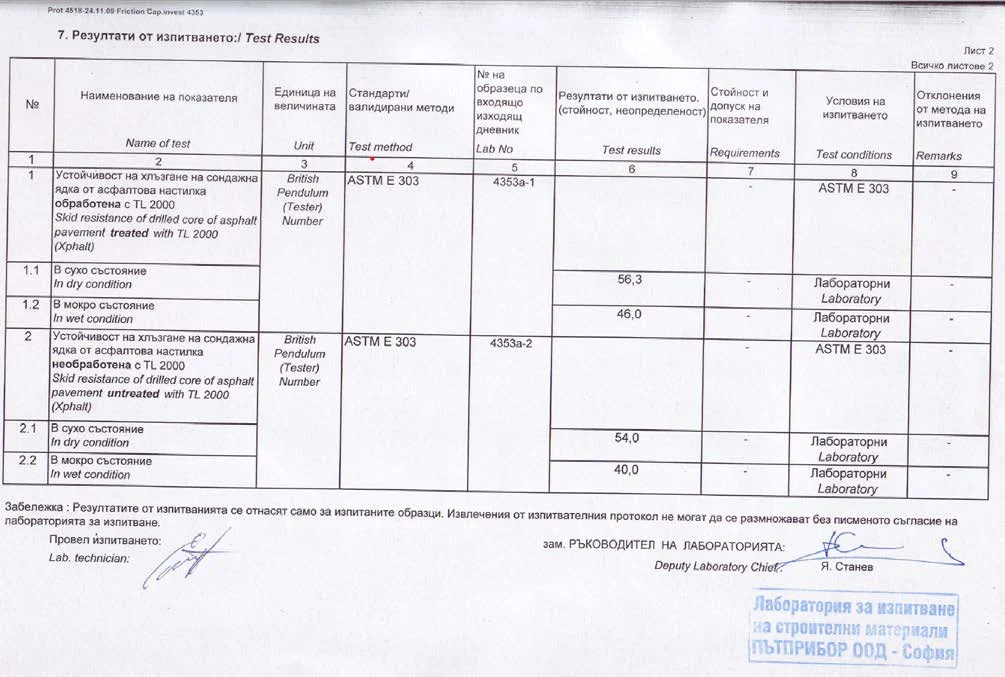

Friction

Lab testing (British Pendulum ASTM E303) indicated little to no reduction in friction after cure.

Operations

Dry‑to‑touch ≈30–45 minutes depending on conditions; predictable reopening for airfield/road environments.

See How Komobility Fits Your Maintenance Program

Frequently Asked Questions

Case Studies:

Road Repair and Sealing Works at Norfolk Island

TL‑2000 (PRS) Spray Trial — Sydney Airport

Examples of the Products Used by ILWONTECH